Testimonial

Royal Mail

PunctureSafe UK was formerly a supplier to Royal Mail, having three times beenawarded either one or three year contracts that had run consecutively,to supply permanent puncture prevention for their fleet of 32,000 vehicles.

PunctureSafe is proven and has stood the test of time with a large blue chip company operating a huge fleet of vehicles. Many companies supplied Royal Mail with their tyre sealant in small trial quantities for them to test, however at the conclusion of these trials PunctureSafe UK was awarded a contract to supply them with permanent puncture prevention treatment throughout the UK and Northern Ireland – testament to both the consistent high performance and cost-effectiveness of PunctureSafe.

Some companies had offered their tyre sealant at very low prices and Royal Mail experienced some major problems with one of these sealants supplied by another manufacturer who initially joined us in a dual supply contract. As problems occurred over time with the cheaper sealant, the dual supply contract was quickly changed to an “exclusive contract” for PunctureSafe UK who went on to be awarded 3 contracts over 5 years.

Our closely guarded manufacturing process produces a premier unique product, so PunctureSafe worked continuously and over time did not cause any issues in the very hot and hostile environment inside the tyres of Royal Mail’s high speed vehicles.

PunctureSafe’s ability and performance is not diminished with speed, distance or time

The Royal Mail supply chain buyer informed us that PunctureSafe was very beneficial and successful because downtime from tyre related problems had been significantly reduced. He also stated that service levels from PunctureSafe UK had been excellent and very professional.

Following testimonial supplied by the former Royal Mail supply chain buyer – category vehicles (contracts manager)

Royal Mail Group have been investigating tyre sealants for some time now because tyre costs annually are considerable and downtime caused by tyre related incidents is a major problem for us.

We were not sure of the difference between the many sealants in the market so we approached a significant number of tyre sealant manufacturers in Europe and the UK, including PunctureSafe. We tested 4 of these products extensively at various Royal Mail depots around the UK, over many months and in different types of vehicles.

We were delighted with the result of these trials and in particular the performance and service levels of PunctureSafe. Our puncture rate has reduced dramatically since we begun using it, and downtime caused by punctures has been reduced significantly.

Initially we awarded two contracts to supply with a view to selecting one company for a solus contract if they could meet all our service criteria and operate at a level consistent with a supplier to a large blue chip company. Unfortunately, the product and some service levels of one of the companies we issued a contract to, did not live up to our expectations. However I am glad to report that the PunctureSafe product lived up to all our expectations so therefore they have been awarded the sole contract to supply puncture prevention for our 32,000 vehicle fleet.

The service that we have had from PunctureSafe UK has always been excellent and very professional and we look forward to a long and rewarding relationship with them.

************

MCIP BSc Hon

Supply Chain Buyer – Category Vehicles

Clyst HoldingS

Puncture Safe Extra Heavy Duty Grade – writING to inform you of the successFUL TRIALS of your plant-grade product. We have NOW introduced the Puncture Safe system into a range of our construction VEHICLES with the SOLE INTENTION of downtime & REPAIR COST REDUCTIONS, OVER the past six months WE HAVE EXPERIENCED FLAWLESS RESULTS USING PUNCTURESAFE IN OUR TYRES AND have also SEEN an improvement in both fuel and handler efficiency DUE TO the tyres remainING at optimum pressure, LESS TIME IS ALSO requireD BY OUR OPERATORS FOR maintenance checks.

As a COMPANY we PRESENTLY ACHIEVE A turnOVER OF TWENTY MILLION YEARLY in construction activitieS and I CAN SAY THAT your product has and will continue to significantLY reducE OUR operational overheads. JUsT AS importantly, PUNCTURESAFE’S VERY impressive organic/‘green’ credentials fits PERFECTLY with our sustainable supply chain culture, and will CONTINUE TO contribute toWARDS our ambitious Carbon-Impact reductioN TARGETS.

I am VERY HAPPY to fully endorse your product, and have recommended to our board that we commence trials with our fleet of road-based vehicles immediately.

Best wishes

Scott Buckland – MEng (Hons) Oxon

Group Liason, Devon Contractors Limited.

Persimmon Homes.

“Persimmon Homes were CONSTANTLY having SEVERE problems with punctures on our site vehicles operating at our many construction sites throughout the North East so we arranged a trial installing PunctureSafe Extra Heavy Duty Grade into one of our Telehandlers. This trial was VERY successful THAT we have extended the use of PunctureSafe to our fleet of site vehicles throughout the North East. We are v EXTREMELY pleased with the installation of PunctureSafe because the savingS MADE in tyre repairs and MUCH LESS vehicle downtime on our construction sites have been substantial.”

Chris Curry, Construction Director,

Persimmon Homes North East.

Ability Matters

“Tyre sealants: OK so we’ve all heard about Tyre sealants? and there are a lot of them on the market! and I have probably tried most of them with varying results. You may believe in using them you may not and to be honest I had all but given up trying to find one that actually works all the time. I had the good fortune to find “PunctureSafe”. I thought, OK on paper it reads like this is the stuff!!!! the sliced loaf has been re-invented!!! So I decided to take the plunge and order a 20litre drum and pump. IT REALY REALY DOES WHAT IT SAYS ON THE TIN and the pump is also brilliant. I know that’s a bit of a cliché but it has not let me down, and I have tried above and beyond its recommended usage.

We’ve all probably got serial puncture offenders in the mobility business?? I have (HAD) a guy literally every other week, puncture after puncture in his scooter. I used PunctureSafe for the first time for him months ago and I have seen him out on his scooter many times, AND NO MORE PUNCTURES!! We now only use PunctureSafe at all our outlets in ALL scooters, powerchairs and wheelchairs…. anything with pneumatic tyres.

Andrew – Ability Consultant.

Astle BMW

“We have used PunctureSafe for almost 3 years, and have had excellent results from the product, and professional support in every way.”

Richard Harvey – Service Advisor.

Devon Advanced Motorcyclist

“PunctureSafe allowed us to continue with our journey safely and without aggravation, and saved us from a potential blow-out on the M4 after collecting 2 very large nails in our rear tyre, and that is why it is one of the many reasons it is so popular with the Devon Advanced Mototcyclists.”

John Taylor & Helen Beer,

South West BMW Club.

South Yorkshire Caravans

“We have been installing PunctureSafe for two years now. PunctureSafe does everything it says it will do, and has helped avoid many potential disasters for our customers.”

Robert Horner.

National Tyres and Autocare

“Many of our customers use their vehicles abroad and have avoided serious problems by using PunctureSafe. It is a fantastic product.”

Stewart Hoyle.

Sussex Cars Ltd.

Further to my conversation today I am happy for you to use the following testimony:- “Sussex Cars Ltd have been selling and servicing Smart cars for over a decade, supplying nearly 3000 cars during the last 12 years, and carrying out 12,500 services over the same period. We offer PunctureSafe to all our customers when they purchase a car and 86% of them will have the product before they collect their new purchase. Almost everyone of them will have PunctureSafe when they replace the car. Talking with the customers the reason they like PunctureSafe is peace of mind that they get, knowing that the vast majority of punctures are not going to be a problem. I cannot recommend the product enough both as a profit centre and as a security for our clients.

Andrew Shipp.

- From: Steve Clarke Clarkson Recycling

- To: ‘Chris’ <mail@puncturesafe.com>

- Sent: Tuesday, 31 January 2012, 16:15

- Subject: Testimonial

Hi Chris

Just a short message to say how pleased we are that we have used your Extra Heavy Duty PunctureSafe. We have used other products in the past but they have proved unsuitable for the conditions we have on site, especially on the area’s which are used for composting where the road surface can be excessively wet and aggressive. We had the Extra Heavy Duty Grade installed for the last year in our JCB Fastrak Trak and 18 ton Bailey Trailer.

The tractor and trailer are used on site to move around processed wood waste, before the inclusion of PunctureSafe we were experiencing many punctures due to loose nails from the wood processing. This cost many hours of down-time and many £££s spent in puncture repairs. Since the installation of PunctureSafe we have had NO puncture and NO down-time.

We have also used the product in our JCB Telescopic Loader and again no punctures even after hundreds of hours of use over the past twelve months.

For delivering our Organic Compost to customers we use a 3.5 ton tipper vehicle, driving up farm tracks and industrial estate roads etc which was causing us to suffer many punctures. We have installed the PunctureSafe Heavy Duty Grade in the tippers tyres and a now NO punctures

Based on our experience I can thoroughly recommend the Extra Heavy Duty Grades for larger site based machines which are prone to punctures and the High Speed Heavy Duty Grade for road going vehicles.

Steve Clarke

Managing Director, ClarkeSon Recycling Ltd, COR Services

BMW Club.

Taken from the Club Journal & reprinted with permission from the Technical Officer Mike Fishwick –

While punctures definitely occur far less nowadays compared to in the 80’s, punctures are still one of the leading problems to afflict the motoring public. BMW are justifying the removal of spare wheels based on claims that claim that they only occur every 93,000 miles. The M Roadster itself has fallen victim too.

To offer odds at all on a random event is something, which no self-respecting bookie would ever dream of! My experience has been that punctures can occur at any time – ask anyone living on a new housing development where nails and screws and other fragments are everywhere. The only guarantee is that punctures will usually occur when one least expects and at the most inconvenient times.

Temporary repair aerosol sealants are a fast way for the motorist to regain mobility but their use can only start once vehicle comes to a stop. Prolonged use is not advisable. Due to the composition of these sealants the majority of tyre specialists refuse to repair punctured tyres, that internally are coated with these sealants.

Most modern motorcycles have ‘Z’ rated low profile tyres and suffering a flat tyre could be a very expensive experience. The fitting of a vulcanised plug isn’t always possible, especially if the puncture is too close to the sidewall. Also in most cases tyre specialists limit only 1 repair per tyre.

Severe damage to the sidewalls not to mention the wheel rims are possible, simply by slowing down to stop from an advanced speed. Extremely life threatening tyre deflation can occur without tyres being punctured such as what almost happened to John Coleman during our return from the FIM Rally at Barcelona. John ran over a rock while climbing towards the Col de I’lseran in the French Alps. The front rim of his R80 became badly deformed that the edge of the tyre bead was visible over a length of about two inches. Just part of an inch deeper and his front tyre would have instantly deflated, leading to a rapid one-way trip to Bonneval – sur – Arc, about a thousand feet below!

The obvious solution to all these problems would be that tyre manufacturers manufactured puncture resistant tyres. But in the absence of tyre companies not doing so an alternative is to coat the inside of the tyre with an anti puncture tyre sealant which will always stay sufficiently fluid to fill the puncture as soon as it occurs. Naturally the sealant should be such that it does not disturb wheel balance, and be capable of being easily removed if required.

Several such products have been marketed over the years, mainly directed at the motorcycle market. While tyre manufacturers do not recommend their use, there is no evidence or proven trusted research showing these sealants to be detrimental. In all known cases of major damage to the front tyre, riders have maintained control and stopped safely.

Most of the sealants worked well even though they had disadvantages. The common problem was that after continued use at high speed the centrifugal force led to the sealant separating thus losing the ability to seal for long periods. Added to this is that it is extremely difficult to remove existing sealant to affect a permanent repair, so that a new tyre was the only effective remedy.

In contrast PunctureSafe tyre sealant appears to be the complete answer. It definitely seals very well – I have personally attacked a motorcycle tyre with a spike until my arm grew tired, at the end of which pressure loss was negligible. Two weeks of such treatment by the public during a motorcycle show and the tyre had more puncture marks than tread, but still maintained it’s pressure. PunctureSafe according to the manufacturer is safely capable of repairing punctures made by objects up to 6 mm in diameter for the life of the tyre, and in the event of a larger area of damage it will provide protection from rapid deflation. It is also water soluble in it’s uncured state, and I have witnessed on occasions the sealant being washed out of a tyre casing without difficulty to enable the fitting of a vulcanised plug. Other properties include the ability to virtually eliminate pressure loss, even during long-term storage, and also to extend tyre life due to improved heat transfer from the tread area to the wheel rim. Many motorcycle riders have found this increase to be in the order of 50%. I’m assuming that this is reason why tyre manufacturers do not recommend its use!

Formulated for use in tubeless tyres, Puncturesafe can also be used with inner tubes, as Cynthia Milton and John Adams demonstrated during their recent trip to Pakistan. John’s RI00GS rear tyre was badly damaged by a two-inch long bolt, but retained pressure well enough to be fitted with a new inner tube later. Cynthia was unaware of any problems, but when replacing her R80GS rear tyre after returning home she found the marks of 12 punctures which had been sealed without her even being aware of them! To cover 20,000 miles on one set of tyres through some of the worst roads in the Middle East and Asia without having to even remove the wheels is sufficient testimony for PunctureSafe. I have used it in my car tyres for almost 20,000 miles, and can also confirm its claims.

A simple vehicle puncture could cost you a full day, and from two to several hundred pounds – can you afford not to use Puncturesafe?!

Mike Fishwick – Technical Officer BMW Club.

Dear Sirs,

Frome 2CV Centre

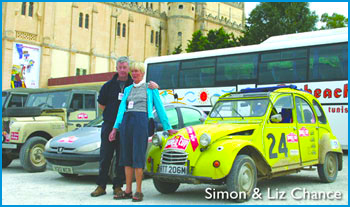

We recently completed our second World Cup Rally in an old Citroen 2CV this time from Oxford to Athens via Austria for all the hill climbs. Driving through Slovenia, Croatia and Bosnia to experience unbelievable off road racing on forest tracks. Then we entered Albania, which has the roughest tarmac roads we have ever seen. On our return we drove home via Italy climbing the mountains of the French Alps to England. A total round trip of 8000 kilometres of which 5000 was under rally conditions.

During this time we started with new Firestone 4 ply tyres (tubed) with the PunctureSafe treatment and never changed one tyre, or suffered any loss of pressure. During last years event we changed 3 tyres and none of them were suitable for future use. Amazingly this year we have 4 tyres, which can all still be used!I think I am correct in saying that we were the only car on the Rally that didn’t have to change tyres at all!

We look forward to using PunctureSafe next year, as it removes all the problems associated with loss of time due to punctures and it improves the overall tyre performance. Well done.

Yours faithfully,

Simon Chance. Director,

Frome 2CV Centre Ltd, Grove Lane,

Marston Trading Estate, Frome, Somerset.

To PunctureSafe

Dear All,

Frome 2CV Centre

Sorry it took so long letting you all know how we got on in our latest exploit. We travelled 8000 kms from Brooklands in Surrey down to Dakar in Senegal, West Africa in January. Once again we didn’t experience any punctures when others around us did, caused by the conditions of heat, sharp stones, very prickly bushes and general debris everywhere.

We have now covered over 20,000 km in total, all completed with the help of PunctureSafe on 3 World Cup endurance rallies in our Citroen 2CV. We covered most of North Africa, over hills and mountains in Europe to Greece and down to West Africa. All credit to you and your product which makes our life so uncomplicated! Many thanks again.

Yours faithfully,

Simon & Liz Chance